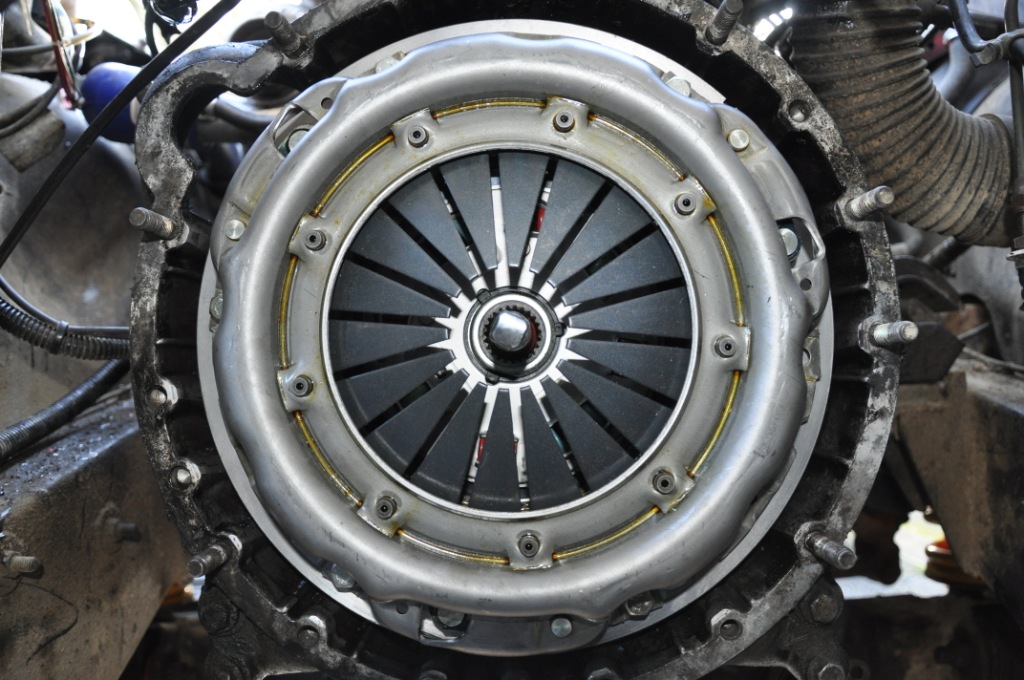

This time last week the car was stranded in Mitcheldever at Better Prepared Vehicles HQ. After spending Monday organising bits at home and waiting for the replacement Britpart flywheel to be delivered we shot down to TJ’s first thing Tuesday. For the rest of Tuesday we fitted the rest of the clutch (now with matching Britpart flywheel!) and set about trying to wrestle the transmission back into the big hole on the underside of the car. With the plan for us to be gone by 6pm Wednesday night, we started at 8.30am re-connecting the various electrical connections to the gearboxes and refitting the removed exhaust, chassis cross member and propshafts.

Not for want of hard work we didn’t quite manage this timeframe but TJ was incredibly generous allowing us to stay an extra night and even have another full day with him Thursday to really try and finish our ‘to do’ list. The one condition however was that we slept in the rooftent for the first time that night. This was something we had both quietly been avoiding until now, saying we had too many other things to be doing than practicing sleeping in a tent. In reality I think we were both a little apprehensive of sleeping in what would be our home for the next 11months – for if we didn’t like it very much that could have become a small issue…

In truth there weren’t any problems with the tent as it was amazingly warm and sturdy -they don’t skimp in wall thickness when they know the tent will be carried by a car and not a person! So on Thursday the lovely new Bosch starter motor and 100amp alternator were fitted before the final bushes to be changed were removed. Typically these were the hardest of all we have done with the nuts having rusted to the bolts to make one solid piece of metal. Many heart in mouth moments followed as the grinder was brought out and kicked and bucked its blade into the rear A-frame bolts just inches from the rear brake line. Eventually through a combination of a cold chisel, a club hammer, lots of wd40, a hacksaw, a small grinder and a frankly massive grinder, the bolts were beaten. After this, time for even found for TJ to show Carl how to check thevalve clearances.

Amongst the on going braking problems a faulty servo unit had been identified so with a little more time with expert guidance this was removed and a new one fitted in double quick time. Everything was flying into position and we were making great time until tightening the final bleed screw whilst bleeding the final brake calliper on the final job of the day. Cue panicked phone calls to friendly engineers who unfortunately weren’t available able to help to get us home that evening. Thankfully TJ was better prepared than us and within a couple of phone calls had a solution sorted. The only downside was we had to wait 2hours to meet a mystery man at a mystery location.

The mystery location turned out to be a workshop of an infamous secretive off-road 4×4 team, of whom two members promptly arrived to lend their expertise and help us get back on the road. And what expertise they were, the calliper thread was quickly deemed unrecoverable but this wasn’t seen as a problem because these could ‘just’ be re-drilled and new threads cut and a brand new bleed nipple made to fit. Yes, made! What followed was one of the most amazing feats of craftsmanship I have ever seen, as one team member Vince machined down a large lump of steel into a perfectly shaped nipple using just a lathe and pushing drill bits into the metal at various points. A few hours later we were back at TJ’s and bled the brakes and rolled on home. Having agreed to have been gone from TJ’s by 6pm Wednesday, we actually left at 11.30pm Thursday and arrived home late. Despite staying far longer than planned TJ was still ever helpful and generous, thanks mate without your help we would be so far behind. We are now in a position where we have completed all the major mechanical work we needed to do to the Landy. This is a bit of a milestone in our prep and at times we both wondered if we would ever get there. Now our focus can well and truly shift from learning mechanics to addressing the challenges of life on the road, and in particular life on the African road.

Back at home, on Friday we popped down to Antares to finalise some fiddly bits of wiring with our battery monitor (so we know exactly how much life our auxiliary batteries have remaining) and then came home to really attack kitting out the back of the car so that all kit could be securely, safely and conveniently packed. After around 4 hours of talking, throwing kit in and out to see where it fits best, the decision was taken to abandon the start of the framework we already had and build a more bespoke layout in wood. Whilst we had a fairly expensive pre-made Land Rover storage system it just didn’t really fit with the kit we plan to carry so we made the tough decision to rip it all out and start afresh. Planning and building such a system is by no means easy as everything must be stowed such that it will stay in place over some of the horrendous roads we will face, items must convenient, accessible and not easily visible to prying eyes whilst all the while trying to use minimal wood to save weight. Auxiliary batteries, water container, safes, fridge and oil cans all needing mounting and boxing in/protection so it is one large jigsaw mounting something without compromising something else. After a lot of head scratching with the help of Papa James a plan was formed and a visit to Wickes was made. As of Sunday night the circular saw has been slightly blunted, glue has been spilled and the garage covered in saw dust but progress has certainly been made! Photos will have to wait until next time, but be sure to tune back for pictures of PJ Home Improvement’s woodwork and the fitting of the huuuge Kryptonite locks supplied by Proppa.

The plan for this week is simple; arrange the rest of the kit we will need for the trip and finish kitting out the back. Once these things are done, there is little to stop us from going away for a week or so into deepest darkest Wales to test everything out.